- Color & Coating

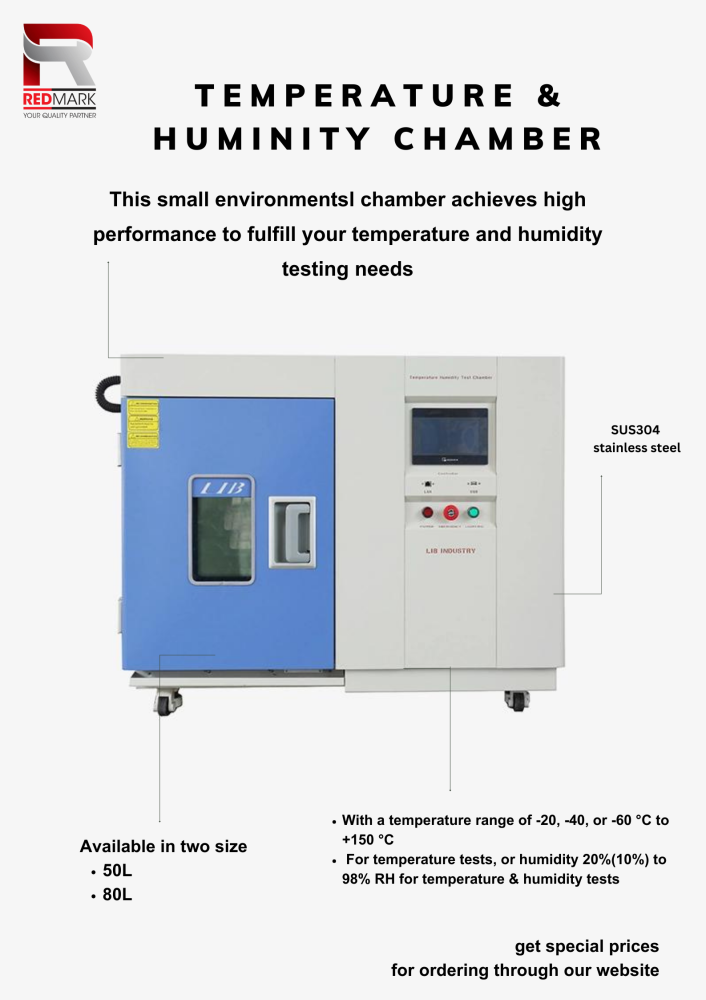

- Environmental Testing Systems

- Temperature Humidity Chamber

- Ozone , Dust , Rain & Noxious Gas Chamber

- Accelerated Weathering Test Chamber

- Salt Spray Test Chamber

- Drying Oven

- Digital Thermometer

- Digital Temperature & Humidity Meter

- Infrared Thermometer

- Moisture Meter

- Anemometer

- Light Meter

- Sound Level Meter

- Particle Counter

- Vibration Machine

- Gas Detector

- Heater

- Others

- View All

- Material Testing

- Universal Testing Machine

- Charpy Pendulum Impact Tester

- BenchTop Hardness Tester

- Ultrasonic Thickness Gauge

- Portable Hardness Tester

- Shore Rubber & Plastic Hardness Tester

- Surface Roughness Tester

- Ultrasonic Flaw Detector

- Melt Flow Rate Meter (MFI)

- Sample Preparation Machine

- Asphalt & Bitument Testing

- Heat Stress Metter

- Plastic Testing Equipment

- Precise Measurement Solution Provider

- Rheometer

- View All

- Metrology Measuring System

- Portable Measuring & Testing Instruments

- Weighing & Metal Detection System

- Electronic & Electrical Testing Equipments

- Lab & Scientific Equipments

- Equipments for Food & Beverage Packaging

- Hot Wire Bottle Cutter

- Vacuum Leak Tester

- Pressure or Vacuum Gauge

- Secure Seal Analyzer

- CO2 Easy / CO2 Easy-DCO2 Measuring Device

- Burn Test

- Can And End Testing Equipments

- CO2 Measure

- Crown Cap Measure & Test

- Cutting Packaging

- Dimensional Measure

- Filtering

- Force Measure/Compresion/Dynamometers

- Stress Aplication

- Torque Measure

- Others

- View All

- Electric Vehicle Equipment

- Ion Fan

- Microscope

- Service Maintenance & Calibration

- Others

Redmark Industry Sdn Bhd

141-2, Jalan Radin Bagus, Bandar Baru Sri Petaling, 57000 Kuala Lumpur, Malaysia.

+6012-499 2103

Redmark Industry (Penang)

Sdn Bhd

7206, Mez Floor, Kompleks Perniagaan Pangsapuri Seri Cemerlang, Jalan Kampung Paya, Kampung Paya, 12200 Butterworth, Penang, Malaysia.

chuin@redmarkindustry.com

Latest News

Deliver & Training LEEB (Portable Hardness Tester)

Oct 24, 2023

Redmark Industry's YEARLY LIB GLOBAL PROMOTION

Oct 20, 2023

Allow us to share the wonderful benefits that this promotion entails:

.png)

Supplier of PCE Instruments UK: Test Instruments

Oct 18, 2023

Supplier of PCE Instruments UK: Test Instruments

PCE Instruments (PCE) is an tools and equipment for measuring, weighing and control systems. Founded by German engineers nearly two decades ago, PCE offers more than 500 test instruments with applications in industrial engineering and process control, manufacturing quality assurance, scientific research, trade industries and beyond. PCE’s large test instrument portfolio includes handheld, desktop, portable or fixed-installation sensors, meters, gauges, scales, analyzers, detectors, data loggers and inspection cameras branded by PCE and other first-class manufacturers from around the globe.In addition, PCE can provide custom test instruments on demand. The DIN EN ISO 9001-certified PCE Product and Development Company GmbH produces test instruments tailored to meet unique customer needs. PCE serves customers from government,

industry and academia in diverse fields such as acoustical engineering, aerospace, agriculture, archaeology, architecture, automotive, aviation, bioengineering, building inspection, chemistry, civil engineering, computer science, construction, data acquisition, education, electrical engineering, energy, environmental science, food processing, forensics, forestry, geology, government, horticulture, HVAC, hydrology, industrial hygiene, law enforcement, library science, logistics, machining, maintenance, manufacturing, materials science, mechanical engineering, metal working, meteorology, military, mining, nondestructive testing (NDT), occupational health and safety, oil and gas, pharmaceuticals, property management, pulp and paper, physics, robotics, structural engineering, supply chain, transportation, tribology, veterinary science, water treatment, welding, woodworking and more. By capitalizing on the expert knowledge and extensive experience of PCE’s engineers.

industry and academia in diverse fields such as acoustical engineering, aerospace, agriculture, archaeology, architecture, automotive, aviation, bioengineering, building inspection, chemistry, civil engineering, computer science, construction, data acquisition, education, electrical engineering, energy, environmental science, food processing, forensics, forestry, geology, government, horticulture, HVAC, hydrology, industrial hygiene, law enforcement, library science, logistics, machining, maintenance, manufacturing, materials science, mechanical engineering, metal working, meteorology, military, mining, nondestructive testing (NDT), occupational health and safety, oil and gas, pharmaceuticals, property management, pulp and paper, physics, robotics, structural engineering, supply chain, transportation, tribology, veterinary science, water treatment, welding, woodworking and more. By capitalizing on the expert knowledge and extensive experience of PCE’s engineers.Supplier of PCE Instruments UK: Test Instruments

Oct 18, 2023

Supplier of PCE Instruments UK: Test Instruments

PCE Instruments (PCE) is an tools and equipment for measuring, weighing and control systems. Founded by German engineers nearly two decades ago, PCE offers more than 500 test instruments with applications in industrial engineering and process control, manufacturing quality assurance, scientific research, trade industries and beyond. PCE’s large test instrument portfolio includes handheld, desktop, portable or fixed-installation sensors, meters, gauges, scales, analyzers, detectors, data loggers and inspection cameras branded by PCE and other first-class manufacturers from around the globe.In addition, PCE can provide custom test instruments on demand. The DIN EN ISO 9001-certified PCE Product and Development Company GmbH produces test instruments tailored to meet unique customer needs. PCE serves customers from government,

industry and academia in diverse fields such as acoustical engineering, aerospace, agriculture, archaeology, architecture, automotive, aviation, bioengineering, building inspection, chemistry, civil engineering, computer science, construction, data acquisition, education, electrical engineering, energy, environmental science, food processing, forensics, forestry, geology, government, horticulture, HVAC, hydrology, industrial hygiene, law enforcement, library science, logistics, machining, maintenance, manufacturing, materials science, mechanical engineering, metal working, meteorology, military, mining, nondestructive testing (NDT), occupational health and safety, oil and gas, pharmaceuticals, property management, pulp and paper, physics, robotics, structural engineering, supply chain, transportation, tribology, veterinary science, water treatment, welding, woodworking and more. By capitalizing on the expert knowledge and extensive experience of PCE’s engineers.

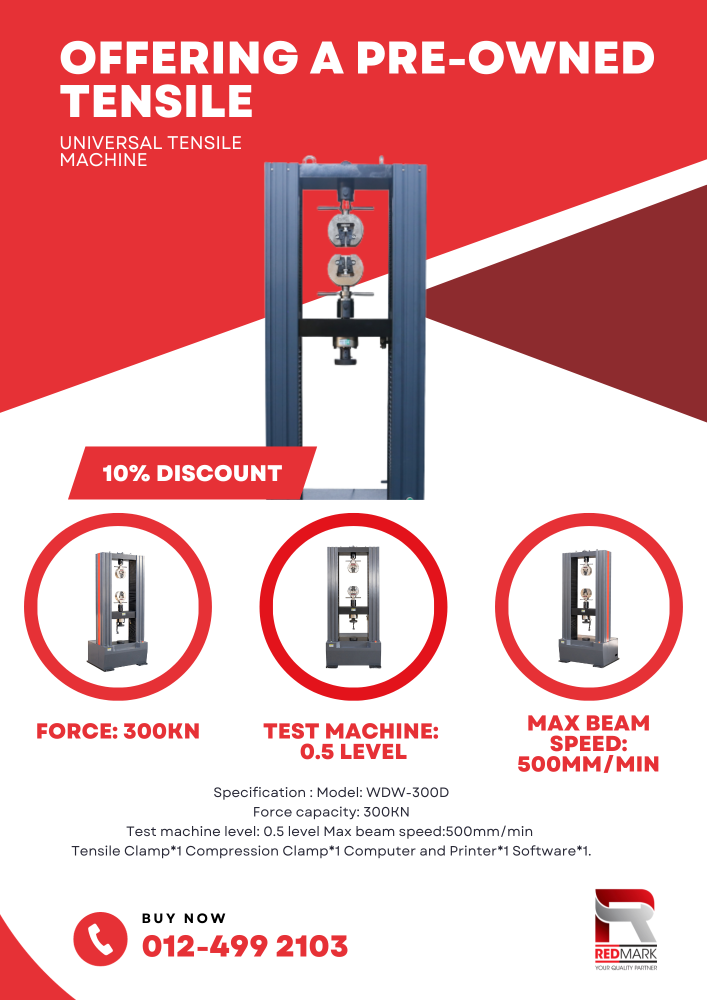

industry and academia in diverse fields such as acoustical engineering, aerospace, agriculture, archaeology, architecture, automotive, aviation, bioengineering, building inspection, chemistry, civil engineering, computer science, construction, data acquisition, education, electrical engineering, energy, environmental science, food processing, forensics, forestry, geology, government, horticulture, HVAC, hydrology, industrial hygiene, law enforcement, library science, logistics, machining, maintenance, manufacturing, materials science, mechanical engineering, metal working, meteorology, military, mining, nondestructive testing (NDT), occupational health and safety, oil and gas, pharmaceuticals, property management, pulp and paper, physics, robotics, structural engineering, supply chain, transportation, tribology, veterinary science, water treatment, welding, woodworking and more. By capitalizing on the expert knowledge and extensive experience of PCE’s engineers.Pre Owned Tensile for Sale - Exciting news !

Oct 16, 2023

🌟 Key Features:

✅ Force capacity: 300kN

✅ Test machine level: 0.5 level

✅ Max beam speed: 500mm/min

✅ Tensile Clamp & Compression Clamp

✅ Computer and Printer

✅ Software and support

Don't miss out on this fantastic opportunity to upgrade your testing lab at a fraction of the cost of new equipment.

Contact us today for details and pricing. Act fast, as quality like this doesn't last long! 💼🔬🏭 #TensileTestingMachine #QualityControl #MaterialsTesting''

Pre Owned Tensile for Sale - Exciting news !

Oct 16, 2023

🌟 Key Features:

✅ Force capacity: 300kN

✅ Test machine level: 0.5 level

✅ Max beam speed: 500mm/min

✅ Tensile Clamp & Compression Clamp

✅ Computer and Printer

✅ Software and support

Don't miss out on this fantastic opportunity to upgrade your testing lab at a fraction of the cost of new equipment.

Contact us today for details and pricing. Act fast, as quality like this doesn't last long! 💼🔬🏭 #TensileTestingMachine #QualityControl #MaterialsTesting''

Preventive Maintenance : Humidity Generator Xenon Chamber

Jul 18, 2023

WE EXPAND EQUIPMENT FOR EV INDUSTRY

Jul 13, 2023

Testing an EV Charging Station / E-charging Station

The quite natural everyday handling of electric current and the high safety precautions common in this country mean that users are not always aware of the dangers of the electric current.  Not only some mistakes in planning and installation of the electrical systems, but also wear and tear, ageing, environmental influences and defects with other causes can lead to protective measures becoming ineffective. To prevent personal injury and damage to property and to ensure the intended function of the electrical installations, there are therefore a number of mandatory regulations.

Not only some mistakes in planning and installation of the electrical systems, but also wear and tear, ageing, environmental influences and defects with other causes can lead to protective measures becoming ineffective. To prevent personal injury and damage to property and to ensure the intended function of the electrical installations, there are therefore a number of mandatory regulations.

An EV charging station is usually connected to the three-phase alternating current with 400 volts in order to be able to generate high charging power. So that the installation or operation of the charging stations did not lead to endangering people, overloading the grid or to the failure of the power-operated equipment and systems, the Charging Station Ordinance was passed in 2016 for publicly accessible charging points in addition to the requirements that apply to every EV charging station. It lays down the minimum technical requirements for safety and also for general accessibility.

Initial and repeat tests

Every EV charging station belongs to the electrical installations on which the initial tests according to DIN VDE 0100-0600 (IEC 60364-6) and repeat tests according to DIN VDE 0105-0100/A1 (IEC 60364-6, Clause 6.5) and VDE 0122-1 (IEC 61851-1) must be carried out by the qualified electricians.  The tests of the e-charging station include inspection, measurement and testing in accordance with the standard specifications with additional consideration of the specifications in the manufacturer's technical documentation. The performance of the tests and their results must be documented in a test report. The tests are primarily intended to determine safety against electric shock and thermal effects, against the effects of lightning and over-voltages, but also the functionality of the system. They are intended to ensure that any defects that may exist are discovered early on and can be remedied before any damage occurs.

The tests of the e-charging station include inspection, measurement and testing in accordance with the standard specifications with additional consideration of the specifications in the manufacturer's technical documentation. The performance of the tests and their results must be documented in a test report. The tests are primarily intended to determine safety against electric shock and thermal effects, against the effects of lightning and over-voltages, but also the functionality of the system. They are intended to ensure that any defects that may exist are discovered early on and can be remedied before any damage occurs.

The first test steps include the visual inspection, the test of continuity and low impedance of the protective conductor and the insulation test. After that, the active measurements are taken at the set charging voltage, including the loop impedance and, for the residual current devices, the RCD tripping time and the RCD tripping current. If a counter is present, the rotating field direction and the correct counter start-up are also checked. To ensure that the communication with the connected vehicle functions correctly, the transmitted CP signal is also checked.

Adapter for simulating charging processes and faults for the measurements

When testing the e-charging station, all the charging states that actually occur should be tested reliably and with the repeatable accuracy without a vehicle. Without the vehicle being connected, however, the charging station must not emit any voltage. Special test adapters can not only simulate the various vehicles charging levels and charging cables. The EVSE adapters also enable convenient measurement of the voltage and signal cables with conventional installation testers simply via the plug connection of the EV charging station.

| CP traffic jams – vehicle charge levels | Resistance CP-PE |

|---|---|

| A No vehicle connected | open |

| B Vehicle connected | 2700 Ohm |

| C Vehicle ready for charging (without ventilation) | 880 Ohm |

| D Vehicle ready for charging (ventilation required) | 240 Ohm |

| E CP error | CP-PE short circuit |

| PP status - charging cable type | Resistance PP-PE |

|---|---|

| NC – no cable connected | open |

| 13 amps | 1500 ohms |

| 20 amps | 680 ohms |

| 32 Amps | 220 Ohms |

| 63 Amps | 100 Ohms |

As a rule, the EVSE adapters are additionally equipped with a function to simulate an earth fault / PE fault. In the event of this and a CP fault (CP status E), the charging process must be interrupted immediately and the plug-in connection of the EV charging station must be disconnected from the power supply. Some adapters also have a manual PE pre-test, which allows the user to check whether the PE line of the EV charging station is safely earthed by pressing a button before the actual tests.

Future Of Evs (Vehicle Electric)

Jul 11, 2023

Electrifying the Automotive Industry: The Rise of Electric Vehicles in Malaysia

The global shift towards sustainable transportation has led to the rapid rise of electric vehicles (EVs) worldwide. Malaysia, as a developing nation with a growing automotive industry, is not far behind in embracing this electric revolution. In recent years, the country has witnessed significant developments in EV manufacturing, infrastructure, and policy support, signaling a promising future for the EV industry in Malaysia.

The Malaysian government has shown strong commitment to promoting the adoption of EVs through various initiatives and policies. One notable effort is the National Electric Mobility Blueprint (EMB), which outlines a comprehensive roadmap for the development of EVs in the country. The EMB aims to establish a conducive ecosystem for EV manufacturing, charging infrastructure deployment, and consumer adoption.

To encourage the purchase of EVs, the government offers incentives such as tax exemptions and rebates. Additionally, the Green Technology Financing Scheme provides financial support for EV-related projects, including manufacturing facilities and research and development activities.

Malaysia has attracted significant investments from both domestic and international players in the EV manufacturing sector. Local companies, such as PROTON and Perodua, have ventured into the production of electric vehicles, contributing to the expansion of the industry.

Foreign automakers, including BMW, Nissan, and Hyundai, have also recognized Malaysia's potential as an EV manufacturing hub. These companies have invested in the establishment of assembly plants and production facilities, leveraging Malaysia's skilled workforce and strategic location in the ASEAN region.

An essential component of the EV ecosystem is the establishment of a robust charging infrastructure network. Malaysia has made notable progress in this regard, with the installation of public charging stations across major cities and highways. Initiatives by companies like ChargEV and GreenTech Malaysia have played a vital role in expanding the charging network and ensuring accessibility for EV owners.

Moreover, the government has encouraged the integration of EV charging facilities in public parking lots, commercial buildings, and residential areas, promoting convenient and widespread charging options.

To stay at the forefront of EV technology, Malaysia has been investing in research and development (R&D) activities. Collaborations between academia, industry, and research institutions have led to advancements in battery technology, electric drivetrains, and vehicle electrification systems.

Research centers such as the Malaysia Automotive, Robotics, and IoT Institute (MARii) and the National Electric Mobility Laboratory (MyEVL) have been instrumental in driving innovation and knowledge sharing within the EV industry.

The Malaysian market presents significant potential for EV adoption. Factors such as rising environmental consciousness, government support, and increasing fuel costs have contributed to the growing interest in electric vehicles among consumers.

Furthermore, the affordability of EVs has improved over time, with advancements in battery technology and economies of scale. As prices become more competitive, coupled with government incentives, the barriers to entry for potential EV buyers are gradually decreasing.

The electric vehicle industry in Malaysia is poised for significant growth. With strong government support, increased investments, the development of charging infrastructure, and ongoing research and development activities, the foundation for a sustainable and thriving EV ecosystem has been laid.

As more Malaysians embrace electric vehicles, the country has the potential to become a regional hub for EV manufacturing and innovation. By leveraging its resources, skilled workforce, and strategic location, Malaysia can contribute to a greener and cleaner future, while driving economic growth in the automotive industry.

DELIVER & TRAINING FOR IP CHAMBER

Jun 27, 2023

We are committed to supporting our customers by providing a comprehensive 3-year warranty and support package, which includes free inspections. Additionally, we offer training programs to ensure that customers can confidently operate new apparatus and equipment that they may not be familiar with.

EID MUBARAK EVERYONE

Apr 20, 2023

Xenon Accelerated Weathering Test Chamber

Apr 17, 2023

PURCHASE RM3K ABOVE GET FREE CALIPER !

Apr 13, 2023

LIB -ENVIRONMENTAL CHAMBER

Apr 4, 2023

MEET WITH OUR SPECIALIST FOR FUTHER INFO

Mar 28, 2023

MEET WITH OUR SPECIALIST FOR FUTHER INFO

Mar 28, 2023

Happy Fasting to All Muslim

Mar 23, 2023

DIGITAL MICRO VICKER HARDNESS

Feb 27, 2023

HEIGH GAUGE DASQUA ! GRAB NOW

Feb 14, 2023

Get your now !

HEIGH GAUGE DASQUA ! GRAB NOW

Feb 14, 2023

Get your now !